Mass production hides mistakes. Small runs expose them.

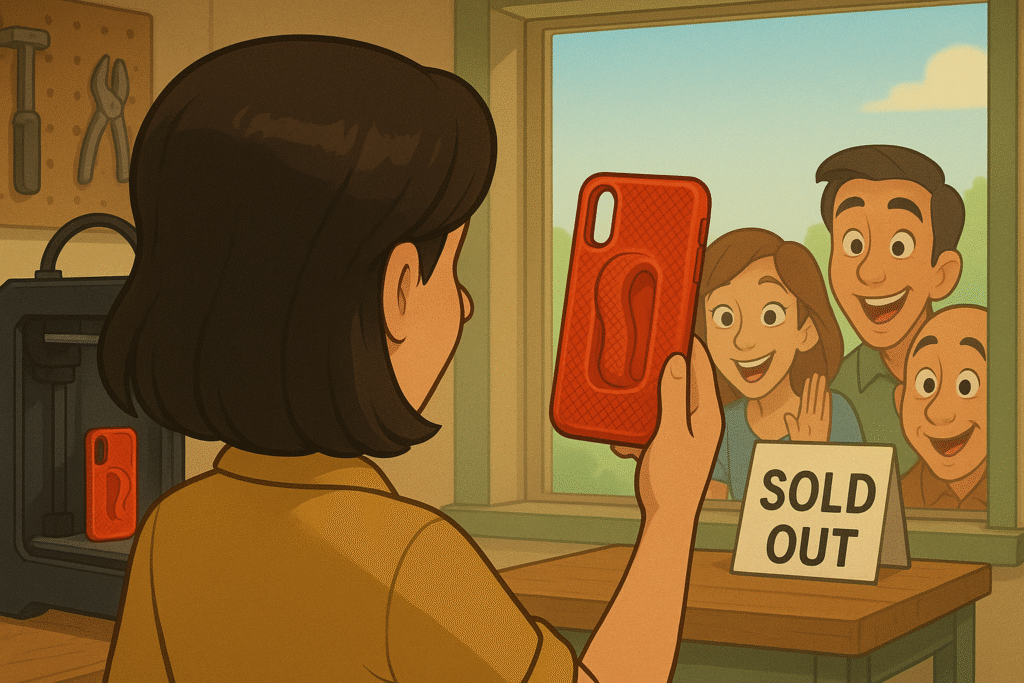

I have a client who tests new product variations in the tiniest runs imaginable — sometimes just a handful of units, with parts 3D printed instead of injection molded.

It massively reduces risk. Because here’s the truth:

People always say they want something. But “want” evaporates the moment they need to pull out a credit card.

The mistake is building 10,000 units on assumptions. (Or worse, 100,000.)

If you can build 10, do it. You’ll learn what people will actually pay for.

Just because they asked for it, that doesn’t mean they will pony up the cash IRL.

And “Sold Out” isn’t something to fear.

It can be awesome.

It proves REAL demand.

Talk is free and can mislead you. Paying lights up a whole different part of the brain.

Better to run out of product than to drown in unsold inventory.

If people need it, they will wait.

(Just mind the gap intelligently. If you continue to take orders when out of stock, be sure customers know WHEN you’ll ship, or platforms like Meta can punish you.)

For small makers, the small-batch mindset turns learning into an asset.

You’re not being inefficient or wishy-washy. You ARE de-risking, gathering proof, and setting yourself up to scale without betting the farm.

Want to make your product irresistible? That’s our jam as go-to-market roadmap consultants at Graphos Product, helping innovators reduce risk while finding the strongest path to scale.