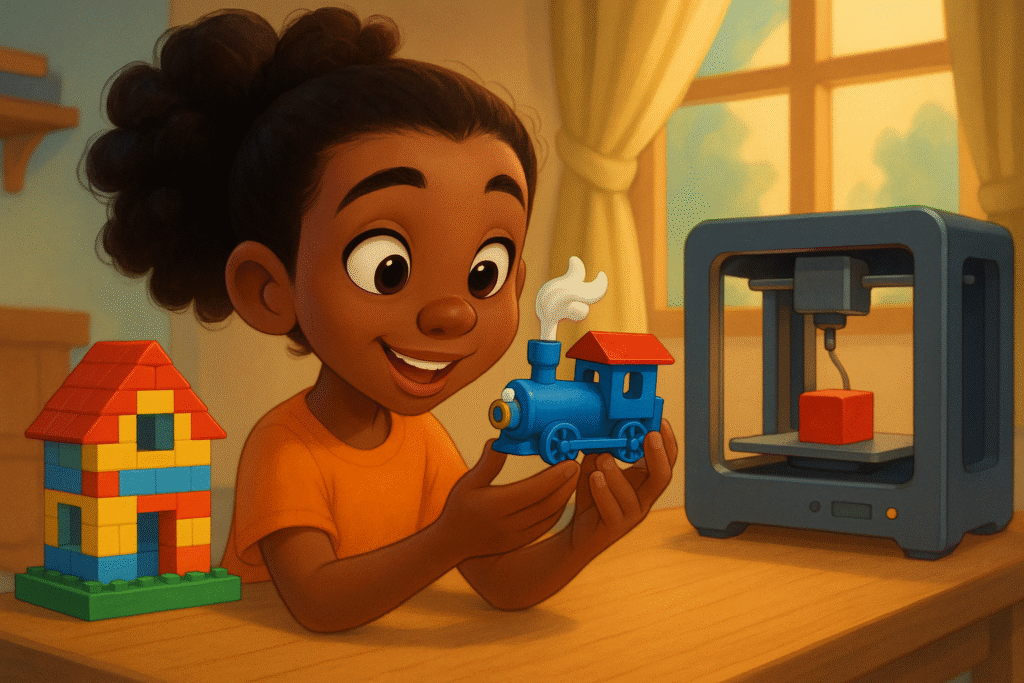

LEGO’s Holiday Express set includes their first mass-produced 3D-printed piece.

LEGO is stepping into additive tech in a big way:

Its new Icons Holiday Express Train will feature a blue-and-red train piece produced via Fine Detail Resolution (FDR) 3D printing.

It’s a for-real watershed — the first time such a piece appears in a mass market LEGO set.

I’m excited by it.

Still, I see trade-offs ahead.

3D printing at high precision is awesome for prototyping, customizations, or low-volume parts.

But quality consistency, cost, appearance, and durability are harder to guarantee than with injection molding.

And brands like LEGO are built on perfect consistency.

Fans expect perfect fit, exact color, and no visible layer lines. Those expectations are high and unforgiving.

FDR is impressive, but can it be that way at scale? LEGO thinks so.

And that vote of confidence signals where manufacturing tech is headed.

Additive is about to get real street cred.

If you’re exploring new materials or print tech, get ahead by testing not just one piece, but many batches.

Find out how the printed parts age, how they feel, and whether they meet visual & functional expectations, before you commit.

Fixing to make your product irresistible? That’s our thing as product marketing consultants at Graphos Product, helping innovators turn need-driven ideas into market-ready successes.